Greater Efficiency, Greater Process Reliability: SEHO Sets New Standards in Selective and Wave Soldering! From November 18 to 21, 2025 the international […]

Greater Efficiency, Greater Process Reliability:

SEHO Sets New Standards in Selective and Wave Soldering!

From November 18 to 21, 2025 the international electronics manufacturing community will gather in Munich for productronica, and of course we will be right in the thick of things – with innovative technologies and upgrades for high-end systems from all product areas!

Experience the world of soldering technology up close with us: Optimized for demanding applications in electromobility and power electronics, impressive with sophisticated process architecture, high flexibility, and consistent focus on efficiency.

Get inspired and see what is already possible today to make your production sustainable and future-ready!

Meet SEHO in hall A4, stand 578!

Our Highlights at productronica 2025

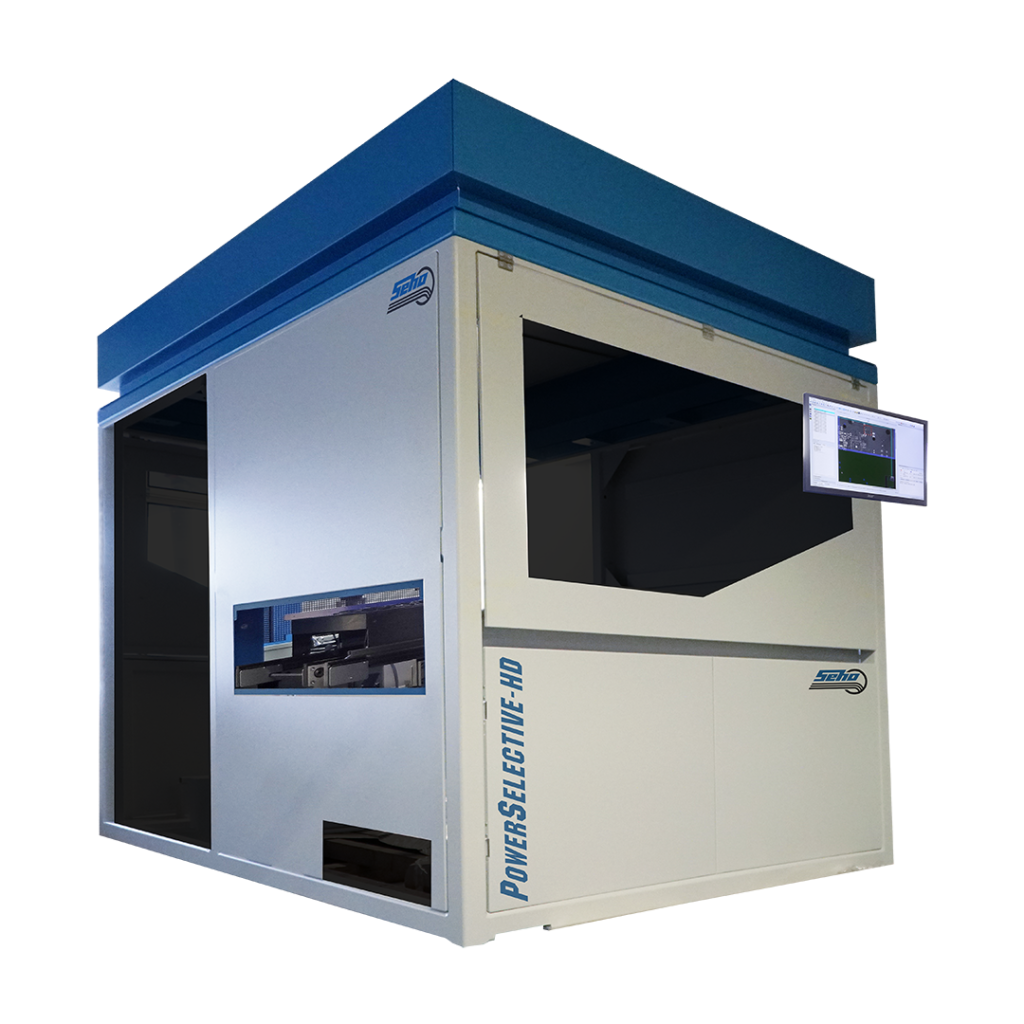

Selective Soldering

The new PowerSelective-HD offers the perfect combination of flexibility, energy-efficiency and process reliability.

A new, innovative cluster preheating concept specifically heats only the relevant assembly areas, significantly reducing energy consumption. The new, flexible soldering unit accommodates several multi-nozzle tools simultaneously, thereby significantly increasing throughput. An eco mode ensures resource-saving operation, while additional integrated processes such as the selective brushing system and THT-AOI system offer maximum process reliability.

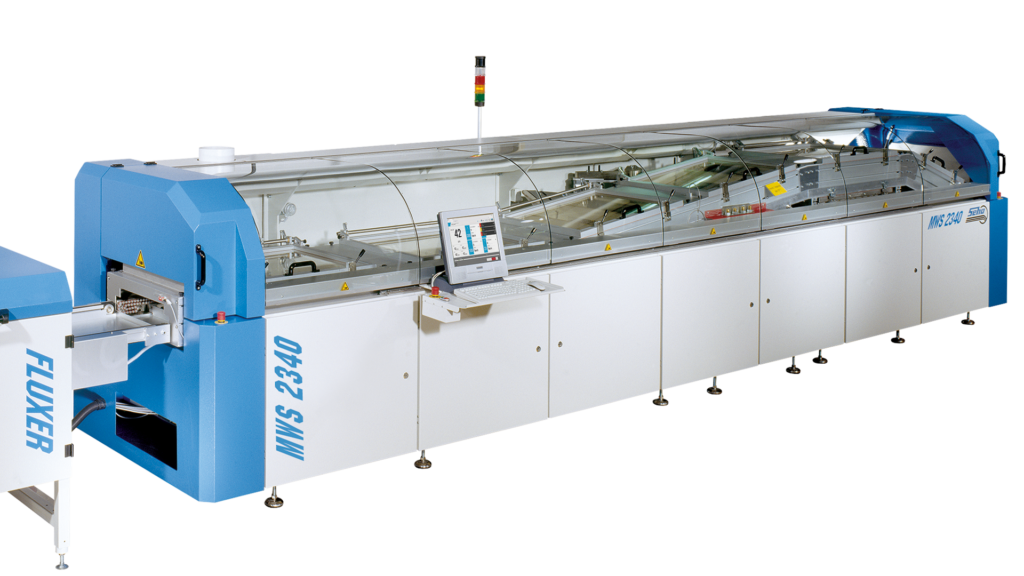

Wave Soldering

Increased efficiency and intelligent process control are also the focus in wave soldering. The segmented flux application enables potential savings of up to 50 % depending on the assembly layout: Only those areas of the assembly where solder joints are actually located are applied with flux. This reduces consumption and maintenance requirements, and also has a positive effect on the process. In addition to the energy savings achieved in the preheating area with innovative pulsar emitters, the newly developed tunnel insulation also significantly reduces resource consumption.

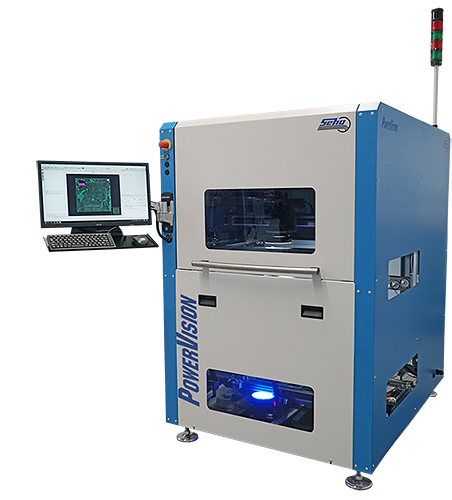

THT Inspection

AOI made easy: The SEHO AssemblyCheck component placement inspection system and the SEHO PowerVision THT-AOI system guarantee the high quality of your products right from the start!

Optimized for the THT process, individually configurable for your manufacturing requirements, and flexibly integrable into the production process.

AOI systems from SEHO focus on two key areas: Continuous quality assurance and cost-efficient manufacturing processes.

Who are actually the faces behind our company?

At home in Bavaria. Active worldwide. Internationally present.

Latest insights from our experts & news from the industry.

Latest dates for various events and trade fair participations.

We are looking for

talent in all areas.

Training or dual studies? We also offer both at the same time!