Thermographic monitoring of flux application sets new standards.

We couldn’t be more proud: Our technology for process-integrated, inline-capable monitoring of flux application, developed in collaboration with SIEMENS AG, Foundational Technologies Berlin, was awarded second place in the Future Markets Cluster at productronica 2025. This award is impressive confirmation of how relevant and forward-looking this development step is for electronics manufacturing.

A breakthrough for a process step that was previously impossible to monitor

The application of flux in wave and selective soldering is a key process step, but one that has been difficult to control until now. Too little flux leads to soldering errors such as incomplete penetration or cold solder joints, while too much can cause residues that can impair the function of the assembly.

Previous monitoring methods are generally based on random sampling or purely functional checks of the fluxer. They therefore do not provide any information about the actual application on the individual printed circuit board.

This is precisely where the new technology comes in: For the first time, it is possible to test every printed circuit board inline and automatically. Not only is the amount of flux applied monitored, but also its exact position.

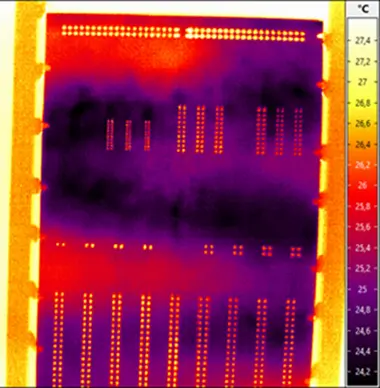

The system utilizes the physical effect that heat is locally extracted from the assembly when the solvent in the flux evaporates. This makes wetted areas appear cooler.

A thermal imaging camera captures this pattern immediately after fluxing and evaluates it intelligently. The analysis is based on a reference model, either a thermographic image or a CAD-based digital twin.

The result is a reliable, highly accurate decision as to whether an assembly is correctly fluxed and approved for the soldering process.

More quality, more efficiency – and the path to autonomous manufacturing

The practical implications are enormous: Incorrect flux application is detected immediately rather than only becoming apparent after soldering, and the corresponding assemblies can be automatically removed from the production line.

This reduces waste, prevents unnecessary rework, and increases process reliability throughout the entire production flow.

At the same time, the technology forms the basis for future AI-supported optimization in real time. The thermographic data collected can be used in the future to automatically adjust process parameters and implement adaptive, self-regulating manufacturing.

As a result, the system not only closes a long-standing gap in process monitoring, but also opens up new possibilities for quality, efficiency, and automation, especially in areas with high requirements.

An award that stands for a strong team

This award is a special achievement for us at SEHO, as it demonstrates what can be achieved when expertise in manufacturing technology, software development, and research come together.

We would like to thank everyone involved for driving this project forward with passion and an innovative spirit, and of course we would like to thank the jury of the productronica Innovation Award for this outstanding recognition.