CERN, the European Organization for Nuclear Research, is one of the world’s most important and renowned centers for fundamental physics research. In its large-scale experimental facilities, scientists investigate the fundamental building blocks of matter and the underlying laws of nature.

Some of the most complex technical systems ever built are used for this purpose.

picture: olrat – stock.adobe.com

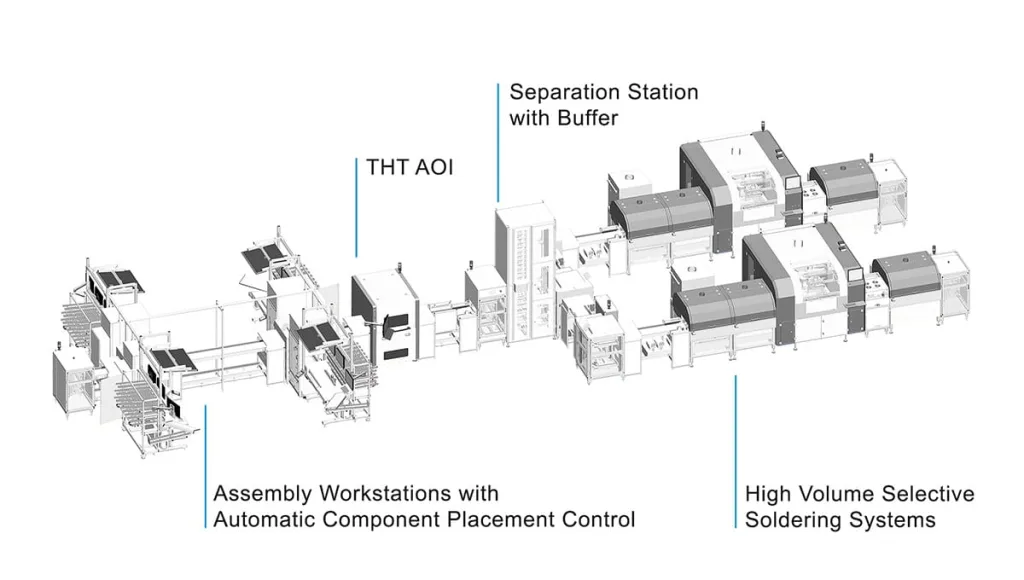

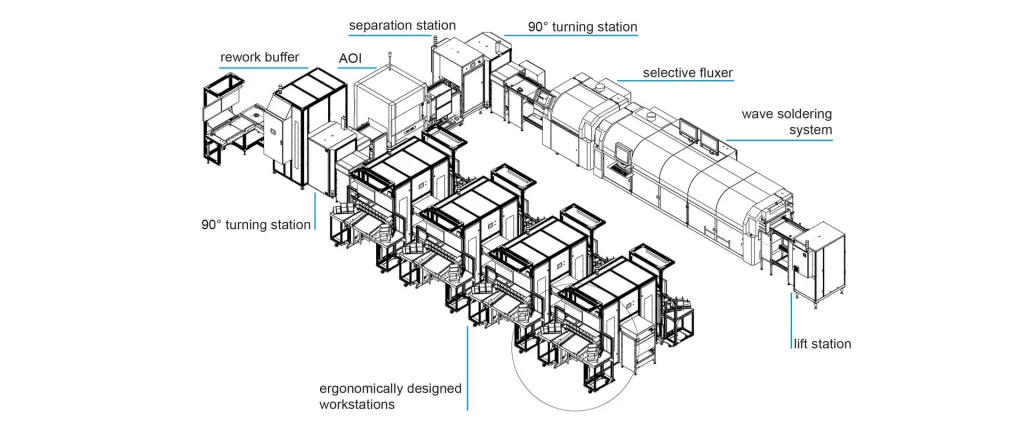

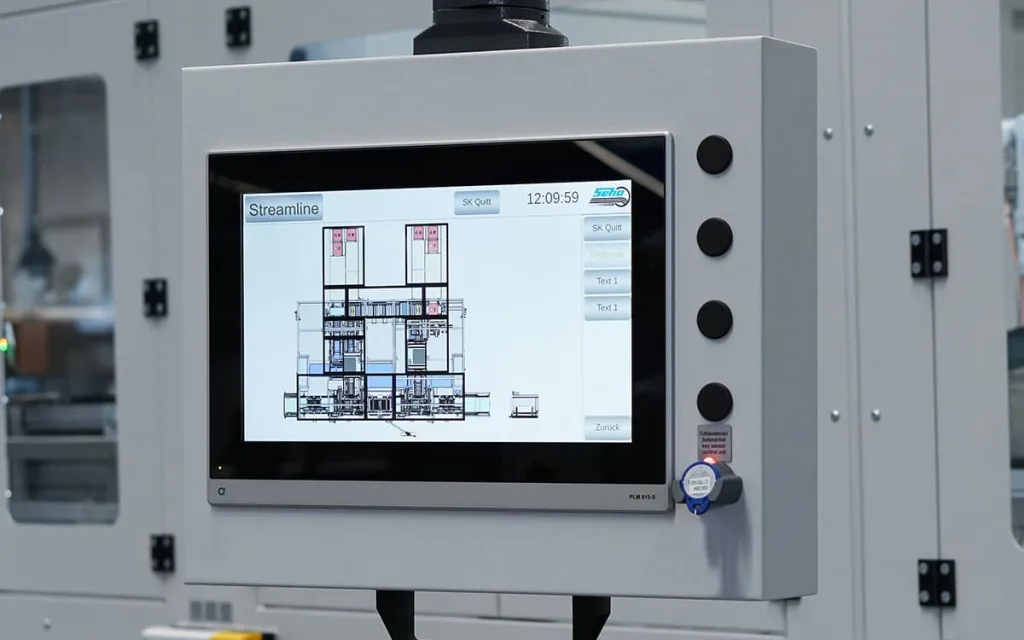

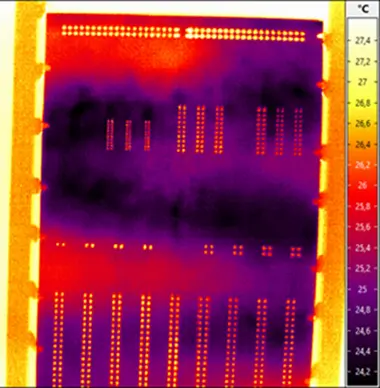

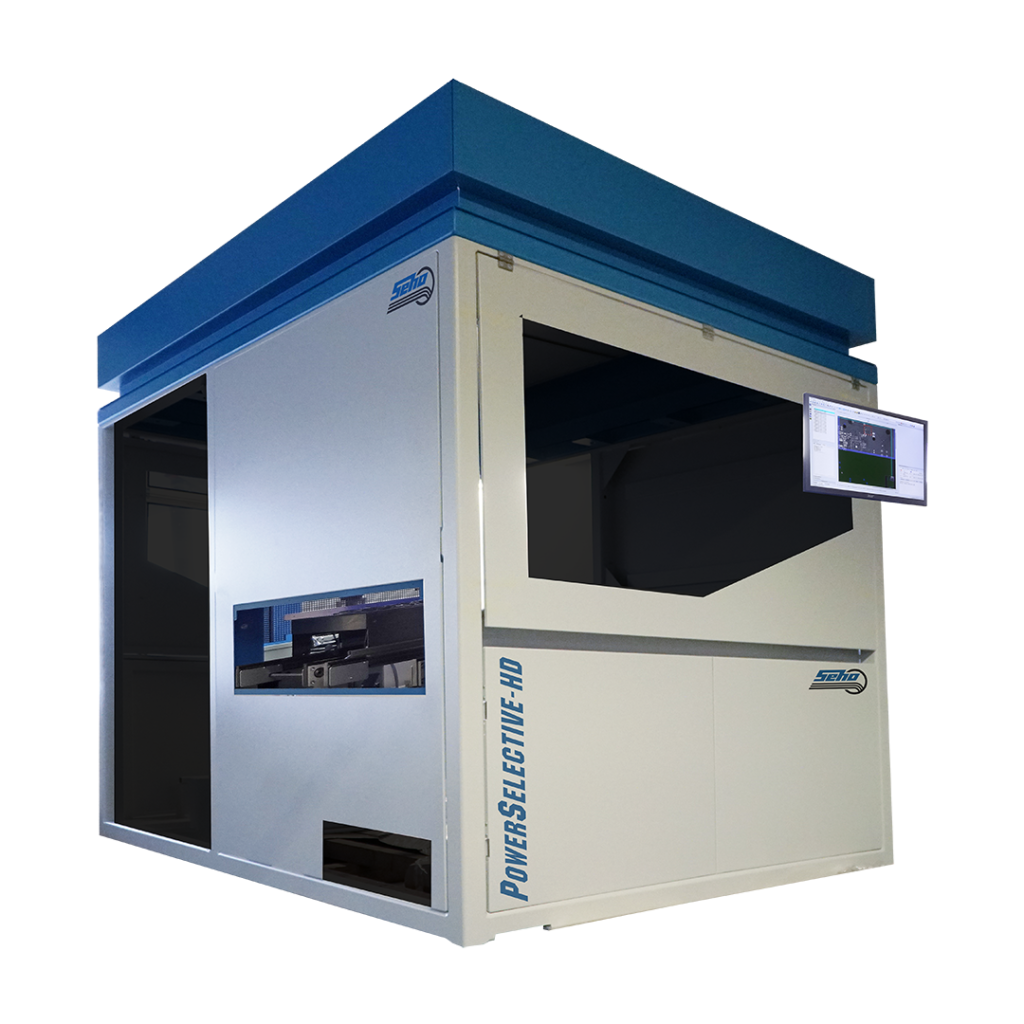

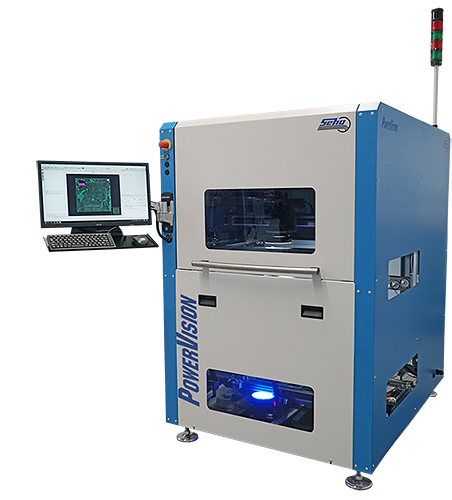

As part of a joint project, SEHO is currently working with CERN on a prototype system for a key process step in the production of non-insulated coils made from high-temperature superconductors. These superconductors are considered as a key technology for high-performance, highly compact magnetic coils that will enable unprecedented magnetic field strengths in future particle accelerators, while also increasing efficiency.

The project is part of the MuCol (Muon Collider) program coordinated by CERN and thus makes an important contribution to the development of the next generation of accelerator technologies.

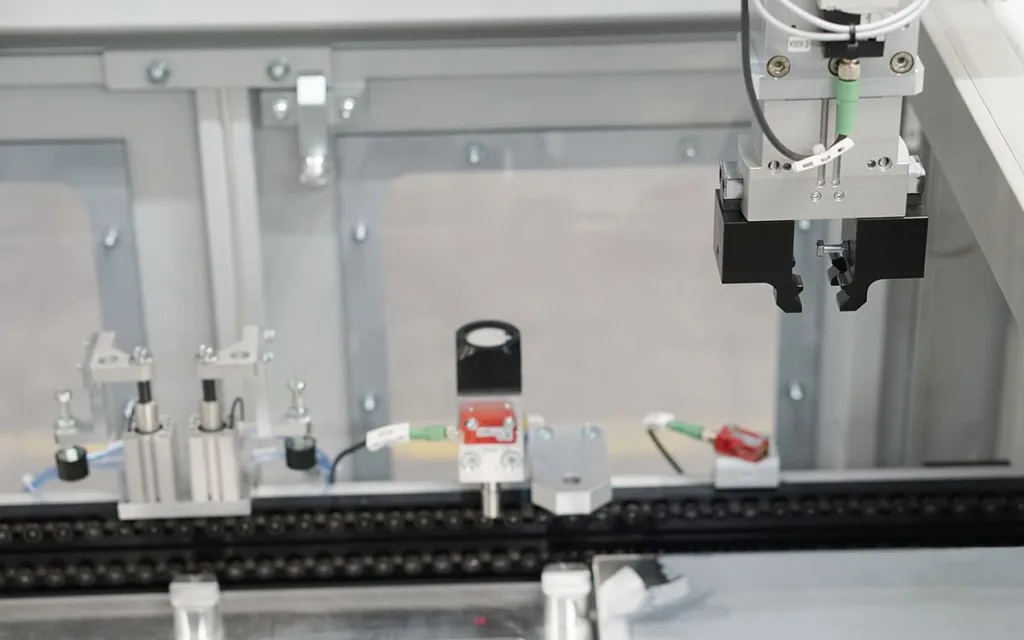

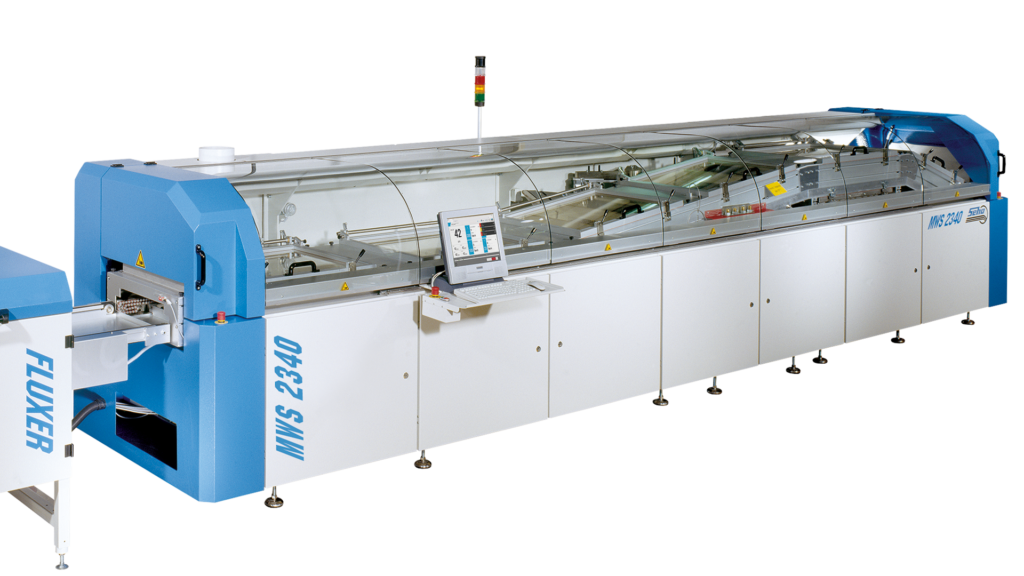

SEHO contributes its many years of experience in the precise handling of liquid solder and in the design of stable, reproducible process sequences. A particular focus is on the controlled and process-reliable application of flux – a decisive quality factor for reliable metallic joints and the functional integrity of the superconducting components.

With this combination of process expertise and system engineering competence, SEHO supports CERN in taking the step from experimental development toward a robust, industrial-grade prototype solution

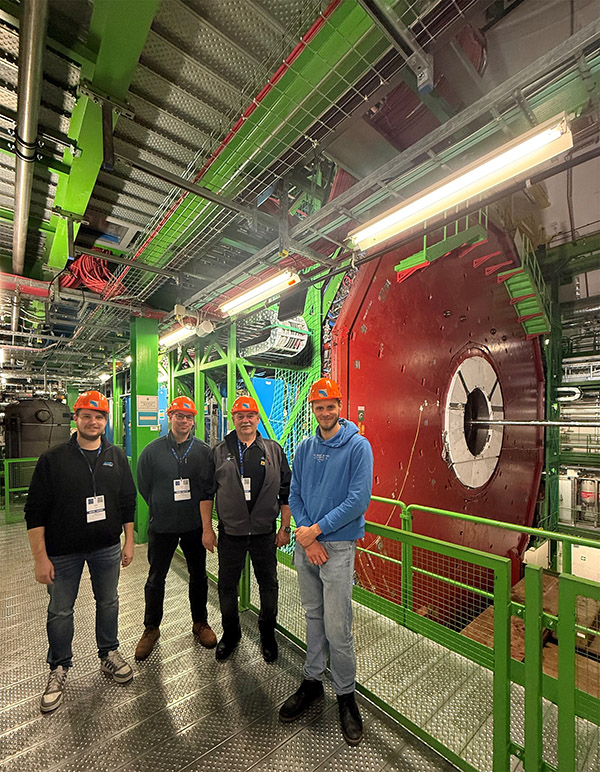

The on-site exchange at CERN was not only to align technical details, but also to develop a shared understanding of the entire process chain – from material science requirements to system-level implementation.

SEHO is excited and proud to be part of this international project and to contribute its technologies in an environment where cutting-edge research and industrial manufacturing expertise are closely linked.