The AOI System PowerVision from SEHO

AOI made easy! The SEHO PowerVision stands for fast, automated, optical inspection and is specially designed for THT processes.

Clear Results

PowerVision focuses on two essential points in the production of THT assemblies: Continuous quality assurance and cost-efficient production processes.

It can be flexibly integrated into any fully automated THT production line or directly into many SEHO selective soldering systems, offering additional benefits.

Depending on the manufacturing requirements, the PowerVision can be configured as needed: For component placement inspection in front of a wave or a selective soldering machine, or for solder joint inspection after wave or selective soldering processes or as a combination of both inspection tasks, integrated into the same module to save space.

It reliably detects typical placement defects such as presence of components or polarity, and soldering defects like incomplete solder joints, solder bridges or solder balls, for instance. Additionally, the system is capable of reading and processing product IDs.

Your Advantages

Highest quality of your products

No undetected soldering defects and continuous quality assurance

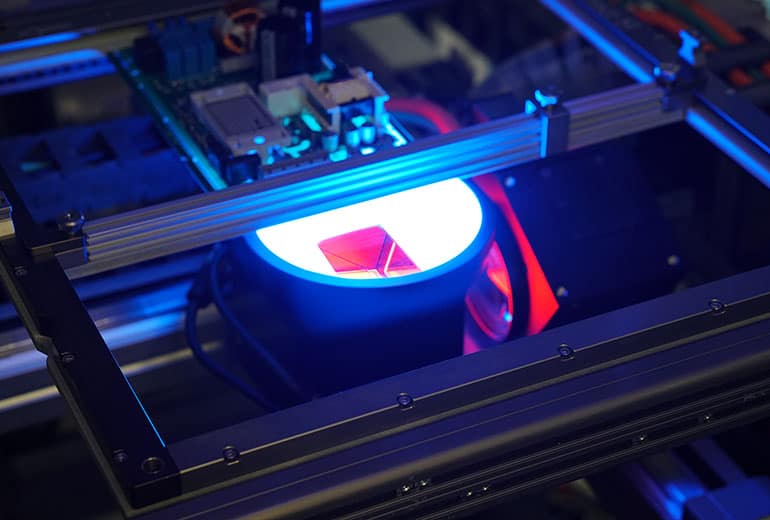

Orthogonal camera unit and multispectral illumination concept guarantee fast analysis and low false call rates

Simple and fast programming

Test plans can be created and optimized easily and conveniently on any PC using an offline teach program

Extensive and individually expandable component library, including component-specific test elements and an automatic inspection search function

Integrated statistical tools enable early optimization of the entire manufacturing process

User-friendly verify software with individually configurable reference image database

Database-driven software architecture = fully traceable processes

As an additional process integrated in many of SEHO’s selective soldering systems

Outstanding reduction of the overall manufacturing costs and maximum ROI

Flexible configuration options allow adaptation to any manufacturing environment

SEHO PowerVision

Fast, automated, optical inspection and specially designed for THT processes. AOI made easy!

Avoid defects before they disrupt the process flow. With AssemblyCheck from SEHO!

Reduce Costs

SEHO AssemblyCheck is a component placement control system that is specifically optimized for THT assemblies.

AssemblyCheck is integrated directly into the assembly workstation and provides immediate feedback whether the components are assembled correctly. Only then can the circuit board be released for further processing in a wave or selective soldering system.

This eliminates possible errors, which leads to a significant increase in quality and yield.

Test features include checks for the presence of the correct components, the correct orientation or polarity component colours are recognized and compared. Typical testing tasks also include OCV, installation positioning and, depending on the application, reading of codes.

Efficient quality assurance right from the start!