How Automated THT Manufacturing Pays Off and Boosts Competitiveness.

Electronics manufacturing is under pressure: product customization and market dynamics demand maximum flexibility while maintaining consistent quality. In the THT sector in particular, it is apparent how much economic success depends on well-designed automation.

No two cars are alike today, modern control technology is built to order, and industrial electronic components are individually tailored to customer requirements – to name just a few examples. At the same time, sales markets fluctuate noticeably, whether due to economic effects, geopolitical influences, or changing customer needs.

The increasing individualization of products and unsteady market demand place high expectations on electronics manufacturing: it must not only be flexible enough to produce a wide variety of assemblies and variants economically but also must be able to efficiently manufacture large series and small, specialized quantities – all while maintaining consistently high quality.

The challenge lies in striking a balance between flexibility, speed, and cost efficiency under increasingly complex conditions.

The demands placed on modern electronics manufacturing often clash with reality, and in addition to technological requirements, the human factor is increasingly coming into focus.

While automated processes are already established in other areas of electronics production, many process steps in THT manufacturing are still carried out manually. This is precisely where bottlenecks are increasingly occurring: skilled labor shortages, absences due to illness, rising wage costs, and higher error rates are putting pressure on production, especially when order volumes fluctuate. In addition, manual tasks affect cycle times and make complete traceability difficult, as processes cannot be recorded digitally throughout.

Step-by-step automation: Tailored to individual needs and scalable

One solution lies in the gradual, demand-oriented automation of THT manufacturing. Finding the right balance is key: complete automation is not always necessary, but targeted partial automation can already achieve noticeable effects – for example, in reducing errors, ensuring consistent quality, or maintaining a stable cycle time.

A scalable approach is essential, whereby the degree of automation can be adapted to the current workload and the vertical range of manufacture.

Equally important is a coherent concept for the interaction between operating personnel and the system. Ergonomic workplace design, simple operating concepts, and clear interfaces between humans and machines promote acceptance and increase efficiency.

When considering the automation of a production area, the future viability of the system should also be taken into account. A flexible concept must be able to accommodate changes in the product life cycle: increasing quantities, additional variants, or a higher degree of automation should be achievable without fundamental modifications.

Individual solutions

THT production lines are rarely standardized but are usually designed individually. The reasons for this can vary greatly and are determined by the products being manufactured, spatial conditions, and human resources. An off-the-shelf automation solution is therefore not very effective. It is crucial to analyze current requirements precisely to develop a concept that fits both the product portfolio and the long-term strategy of the company. In the best-case scenario, the result is a production line that can be expanded, i.e., that grows with future requirements, whether through the integration of additional workstations, the connection of further automation units, or integration into smart production networks.

This results in demand-oriented scaling and a phased investment. At the same time, the personnel on the production line are “taken along” step by step.

THT automation in practical application

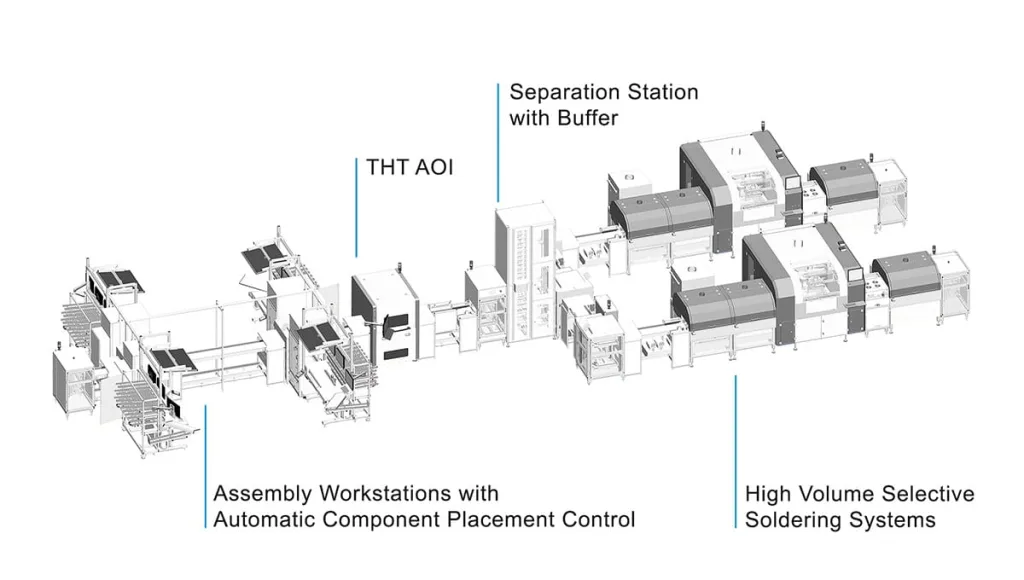

A practical example shows what such a solution could look like: SEHO has implemented a complete THT production line with automatic soldering frame management for an electronics manufacturer on an area of only 120 square meters.

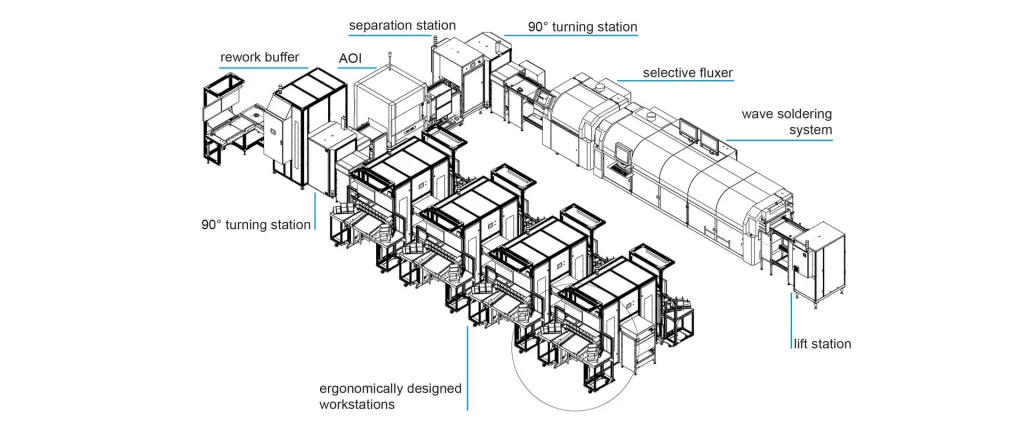

The entire line concept, including a SEHO wave soldering system, is arranged in U-shape and designed for high production volumes. To use the space as efficiently as possible, the eight assembly workstations required were arranged in four opposite positions, each using a shared main transport segment to the manufacturing line.

Ergonomic considerations were a key focus when planning the workstations, with individually height-adjustable tables, tiltable units for assembling components, material storage areas, and line side racks in which the assembly components are arranged clearly and within easy reach. From a logistical point of view, the integrated line side racks also offer the advantage that they can be set up anywhere, thus avoiding unnecessary interruptions.

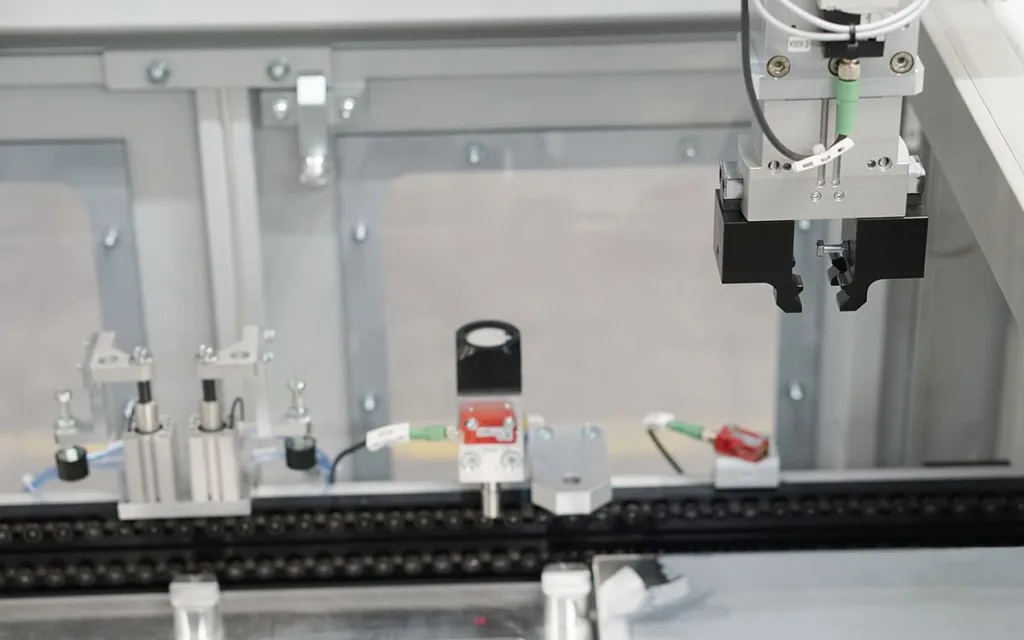

Once a PCB is fully assembled, the soldering frame is transferred from the workstation to the main transport system at the touch of a button by a handling unit, fully automatically and with automatic height adjustment. Each assembly passes through a THT AOI system, which enables complete inspection of assembly quality. Defective assemblies are identified via a separation station and automatically returned to the original workstation, while correctly assembled boards can proceed directly to the wave soldering system.

After the soldering process, the soldered assemblies are lowered to the return conveyor level and pass through the AOI system again for solder joint inspection. Fault-free soldering frames are then transported to the respective workstations. A central rework buffer, in which faulty assemblies are buffered until further processing, prevents backlogs.

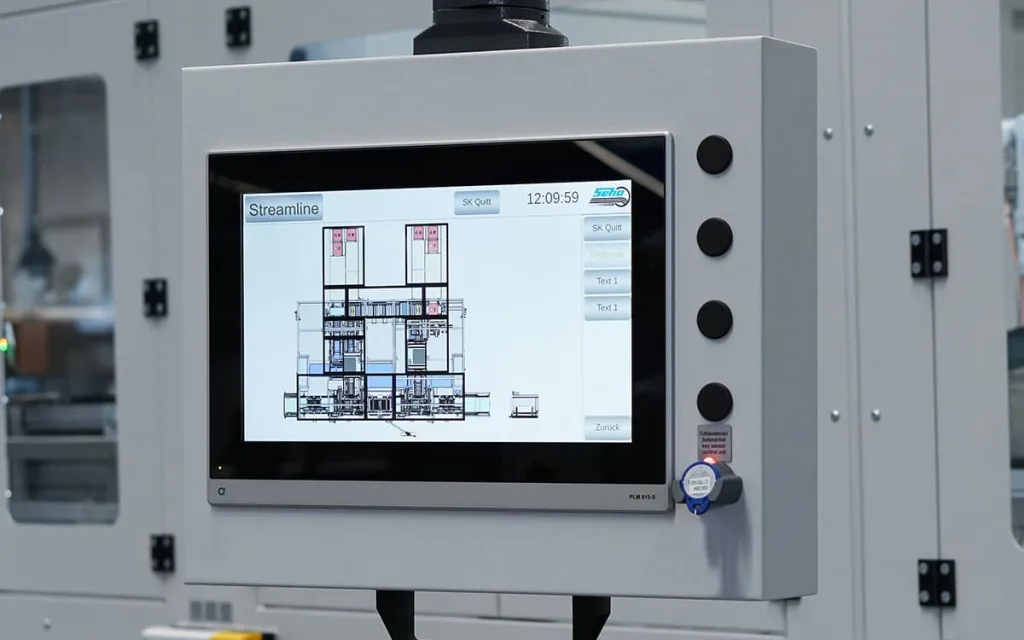

The path of the soldering frames within the manufacturing line is automatically controlled via RFID. As an alternative, the line can be equipped with barcode readers or other identification systems.

The degree of automation of such a production line can be flexibly expanded, for example, by using lightweight robots for assembly, which can be integrated centrally into the manufacturing line or decentrally at individual workstations.

Driverless transport systems (AGVs) also offer potential: they ensure a continuous flow of materials and take over the automated transport of assemblies to the next step in the manufacturing process.

This approach can gradually increase overall production efficiency while relieving operating personnel of non-value-adding activities.

Automated complete solutions

Automated complete solutions that virtually eliminate the need for manual intervention can make the production of THT assemblies even faster and more precise.

In one such project, SEHO developed a fully automated production cell in which all process steps are automated.

This includes assembly with subsequent automatic inspection, insertion of assemblies into workpiece carriers, automatic carrier closure, unloading of workpiece carriers after soldering, solder joint inspection and final automated pass/fail sorting – all without personnel involvement.

The assemblies processed in this system are also controlled via a code reading system connected to a host computer.

This results in a fully digitized process offering maximum transparency, consistent quality and minimal personnel requirements.

Conclusion: THT automation ensures productivity and competitiveness

The appropriate level of automation required depends on the specific application. Not every production line needs to be fully automated. It is more important that the chosen solution is suitable for the product, budget and planned development of the production site.

Scalable automation opens up the possibility of moving toward the future with a step-by-step investment – starting with basic automation and progressing to a fully automated production line. It is worth considering future expandability from the outset of the planning phase. The more prepared the system is, the easier it will be to integrate future requirements, whether due to increased quantities, new product variants, or additional process steps.

The benefits are obvious: automated processes ensure stable workflows and shorter throughput times, significantly increasing overall efficiency in production. Sources of error that can occur in manual processes are reduced, with positive effects on product quality and rework. They relieve staff of repetitive tasks and enable complete traceability.

For electronics manufacturers who want to remain competitive in the long term, automation in the THT sector is therefore becoming a strategic factor.

Want to learn more?

Visit our Automation page.

FAQ about Automation in THT Manufacturing

Automation eliminates typical bottlenecks such as staff shortages, fluctuating cycle times, and high defect rates in manual processes. It ensures more stable processes, end-to-end traceability, and minimizes downtime, which can quickly become critical when order situations change.

While SMT manufacturing lines have been highly automated for years, THT manufacturing involves many manual steps, such as handling of soldering frames, assembly, and quality control. This results in greater dependence on staff availability and manufacturing routines. Automation reduces precisely this variability.

Even individual steps such as automated soldering frame handling, inline AOI, or ergonomically standardized assembly workstations significantly increase process stability. These investments quickly pay for themselves, especially with changing quantities or variant production, because they reduce scrap and make throughput predictable.

Conditions are changing: product variants, batch sizes, vertical range of manufacture. A scalable concept enables the integration of robots, AGVs, or additional workstations at a later date without having to rebuild the basic structure of the line. This reduces future investment risks and makes it easier to balance the peak loads.

THT products differ in terms of geometry, weight, thermal requirements, and handling. Standard systems quickly reach their limits here. A customized solution optimizes material flow, space requirements, transport concept, and user interfaces precisely for the respective product portfolio, thereby achieving higher OEE values.

The production line, which covers just 120 square meters, combines a U-shaped layout, ergonomic assembly workstations, automatic soldering frame transfers, a THT AOI with component placement control and solder joint inspection, and a wave soldering system to form a continuous production concept. The automatic return of defective assemblies and the management of soldering frames via RFID ensure high process reliability and clear material flows.

In fully automated THT production cells, all process steps – component placement control, workpiece carrier handling, soldering, AOI, sorting – run without manual intervention and are fully digitized. This results in reproducible quality, stable cycle times, reduced personnel requirements, and clear traceability throughout the entire process.

Automated processes ensure improved cycle times, less rework, and high machine availability. At the same time, employees are relieved of non-value-adding activities, allowing them to focus on skilled tasks. This helps to maintain production even during periods of labor shortages and cost pressures.